- HOME

-

SOLUTIONS

-

DATA CENTER

Engineering Construction Data Center

-

ENGINEERING CONSTRUCTION

Hydroelectric Power Plant Thermostat Concrete mixing plant operations

-

NEW ENERGY

New Energy Vehicles New Energy Battery Cooling & Storage

-

PHARMACEUTICAL INDUSTRY

Pharmaceutical Industry

-

BIOTECHNOLOGY

Biotechnology

-

PETROCHEMICAL

Oilfield Chemical industry

-

ENVIRONMENTAL APPLICATIONS

Wastewater/Wastewater Treatment Environmental applications

-

NEW MATERIAL

Material Surface Treatment

-

AQUACULTURE

-

COMMERCIAL HVAC

-

SEMICONDUCTOR

-

FOOD & BEVERAGE

-

RAIL TRANSPORTATION

-

MACHINERY AND EQUIPMENT

-

DATA CENTER

-

PRODUCTS

-

COOLING/HOT WATER UNITS (HEAT PUMPS)

- AIR-COOLED CHILLER (HOT) WATER UNIT

AIR-COOLED MAGNETIC LEVITATION CHILLER (HOT) WATER UNIT AIR-COOLED CENTRIFUGAL CHILLERS (CHILLERS) AIR-COOLED SCREW CHILLER (HOT) WATER UNIT AIR-COOLED SCROLL TYPE CHILLER (HOT) WATER UNIT AIR-COOLED PISTON CHILLER (HOT) WATER UNIT

- WATER-COOLED CHILLER (HOT WATER) UNITS

WATER-COOLED MAGNETIC LEVITATION CHILLER (HOT) WATER UNIT WATER-COOLED CENTRIFUGAL CHILLERS (HEATERS) WATER-COOLED SCREW CHILLER (HOT) WATER UNIT WATER-COOLED SCROLL CHILLER (HOT) WATER UNIT WATER-COOLED PISTON CHILLER (HOT WATER) UNITS

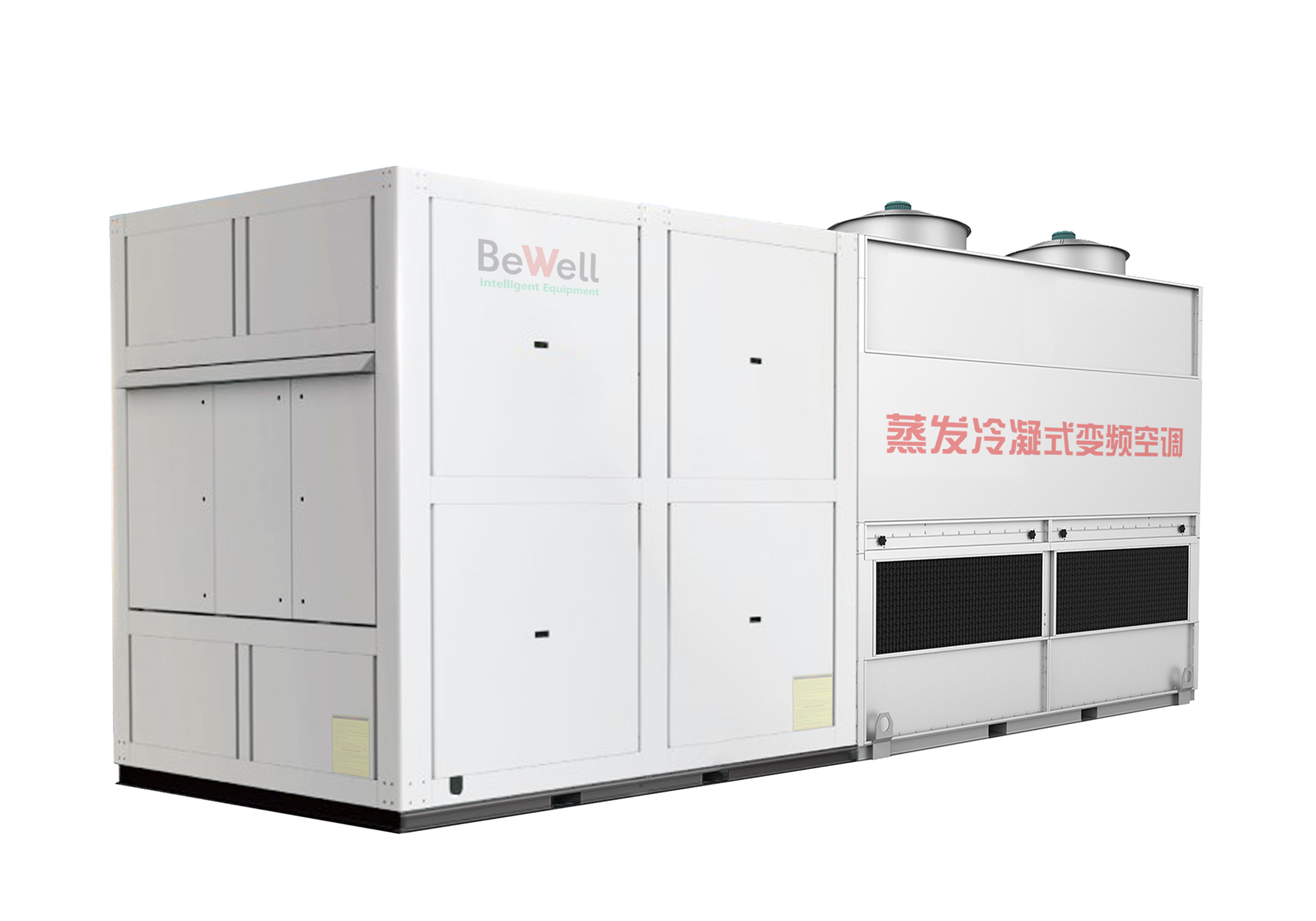

- EVAPORATIVE CHILLERS (HEATERS)

EVAPORATIVE-COOLED MAGNETIC LEVITATION CHILLER (HEATER) EVAPORATIVE COOLING CENTRIFUGAL CHILLERS (HEATERS) EVAPORATIVE-COOLED SCREW CHILLER (HOT) WATER UNIT EVAPORATIVE COOLED SCROLL TYPE CHILLER (HOT WATER) UNIT

- AIR-COOLED CHILLER (HOT) WATER UNIT

-

FREQUENCY CONVERSION TYPE UNIT

- AIR-COOLED INVERTER

AIR-COOLED MAGNETIC LEVITATION INVERTER UNIT AIR-COOLED CENTRIFUGAL INVERTER UNIT AIR-COOLED SCREW TYPE INVERTER UNIT AIR-COOLED SCROLL TYPE INVERTER UNIT

- WATER-COOLED INVERTER

WATER-COOLED MAGNETIC LEVITATION INVERTER UNIT WATER-COOLED CENTRIFUGAL INVERTER UNIT WATER-COOLED SCREW TYPE INVERTER UNIT WATER-COOLED SCROLL TYPE INVERTER UNIT

- EVAPORATIVE COOLING INVERTER

EVAPORATIVE-COOLED MAGNETIC LEVITATION INVERTER UNIT EVAPORATIVE COOLING CENTRIFUGAL INVERTER UNIT EVAPORATIVE COOLING SCREW TYPE INVERTER UNIT EVAPORATIVE COOLING SCROLL TYPE INVERTER UNIT

- AIR-COOLED INVERTER

-

LOW TEMPERATURE TYPE UNIT

- 0℃ TO -35℃

WATER-COOLED LOW-TEMPERATURE AIR-COOLED LOW TEMPERATURE EVAPORATIVE COOLING LOW TEMPERATURE

- -35℃ TO -55℃

AIR-COOLED LOW TEMPERATURE WATER-COOLED LOW TEMPERATURE EVAPORATIVE COOLING LOW TEMPERATURE

- -60℃ TO -180℃

AIR-COOLED LOW TEMPERATURE WATER-COOLED LOW TEMPERATURE EVAPORATIVE COOLING LOW TEMPERATURE

- 0℃ TO -35℃

-

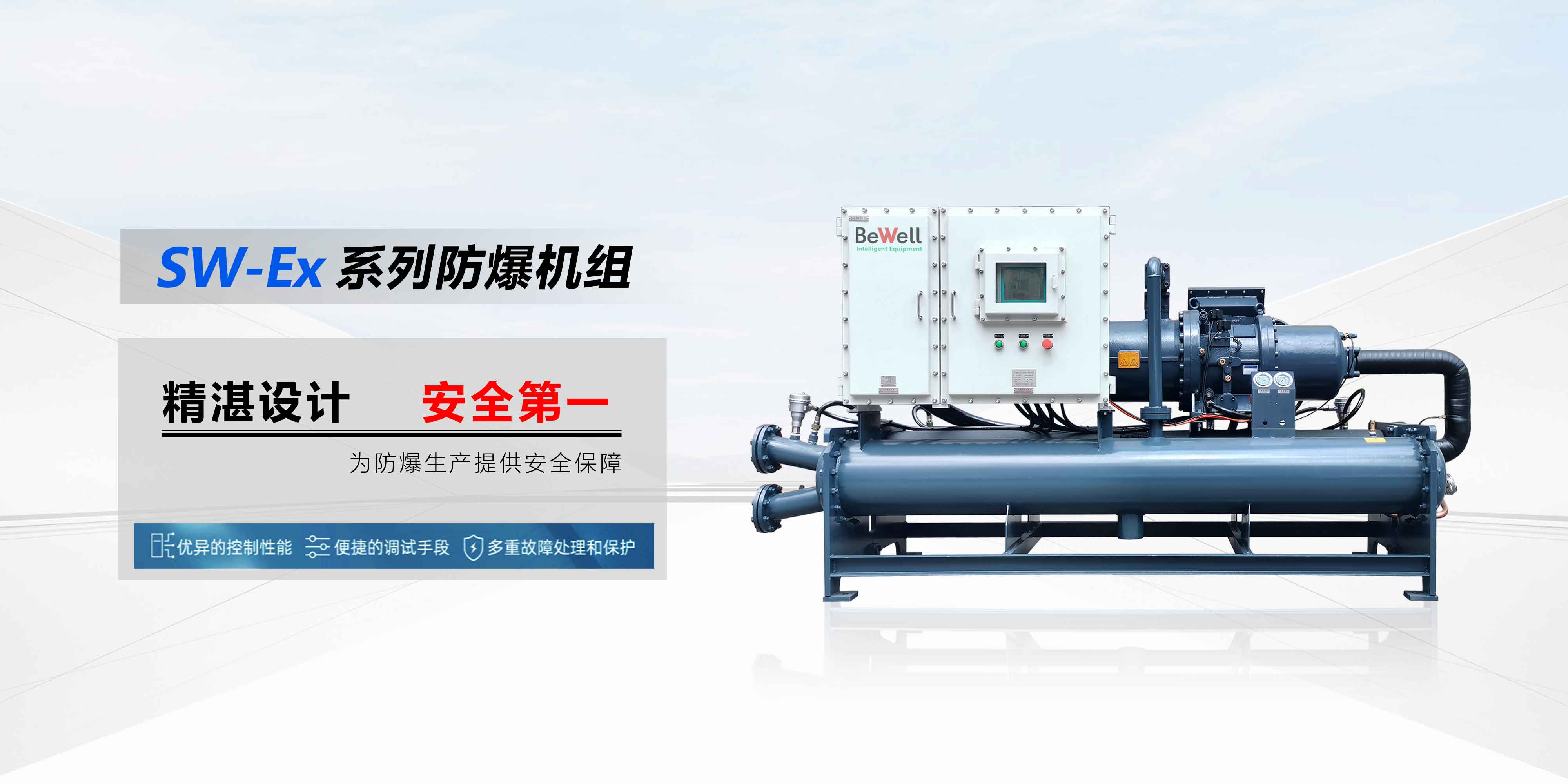

EXPLOSION-PROOF UNIT

- Ex-dIIBT4

AIR-COOLED EXPLOSION-PROOF WATER-COOLED EXPLOSION-PROOF EVAPORATIVE COOLING EXPLOSION-PROOF

- Ex-dIICT4

AIR-COOLED EXPLOSION-PROOF WATER-COOLED EXPLOSION-PROOF EVAPORATIVE COOLING EXPLOSION-PROOF

- Ex-dIIBT4

-

HIGH PRECISION TYPE UNIT

- ±0.5℃ PRECISION

AIR-COOLED WATER-COOLED EVAPORATIVE COOLING

- ±0.1℃ ACCURACY

AIR-COOLED WATER-COOLED EVAPORATIVE COOLING

- ±0.5℃ PRECISION

-

CORROSION-RESISTANT UNIT

- ACID RESISTANT

AIR-COOLED ACID-RESISTANT UNIT WATER-COOLED ACID-RESISTANT UNIT EVAPORATIVE COOLING ACID RESISTANT UNIT

- ALKALI RESISTANT

AIR-COOLED ALKALI-RESISTANT UNIT WATER-COOLED ALKALI-RESISTANT UNIT EVAPORATIVE COOLING ALKALI RESISTANT UNIT

- ANTI-RUST TYPE

AIR-COOLED ANTI-RUST UNIT WATER-COOLED RUST-PROOF UNIT EVAPORATIVE COOLING RUST-PROOF UNIT

- ACID RESISTANT

-

HEAT RECOVERY TYPE UNIT

- WASTE HEAT RECOVERY

AIR-COOLED HEAT RECOVERY WATER-COOLED HEAT RECOVERY EVAPORATIVE HEAT RECOVERY

- FULL HEAT RECOVERY

AIR-COOLED HEAT RECOVERY WATER-COOLED HEAT RECOVERY EVAPORATIVE HEAT RECOVERY

- WASTE HEAT RECOVERY

-

MOLD TEMPERATURE UNIT

- WATER TYPE MOLD TEMPERATURE CONTROLLER

120℃ MOLD TEMPERATURE MACHINE 250℃ MOLD TEMPERATURE MACHINE 350℃ MOLD TEMPERATURE MACHINE

- OIL TYPE MOLD HEATER

120℃OIL TEMPERATURE MACHINE 250℃OIL TEMPERATURE MACHINE 350℃ OIL TEMPERATURE MACHINE

- WATER TYPE MOLD TEMPERATURE CONTROLLER

-

AUXILIARY EQUIPMENT

- COOLING TOWER

COUNTERFLOW COOLING TOWER CROSS-FLOW COOLING TOWERS MIXED-FLOW COOLING TOWER

- HEAT EXCHANGER

DRY COOLER SURFACE COOLER COLUMN TUBE PLATE EXCHANGE

- INSULATED WATER TANK

STAINLESS STEEL TANKS GALVANIZED WATER TANK

- COOLING TOWER

-

COOLING/HOT WATER UNITS (HEAT PUMPS)

- ABOUT US

- NEWS

- CONTACT US

185-0301-1521

185-0301-1521